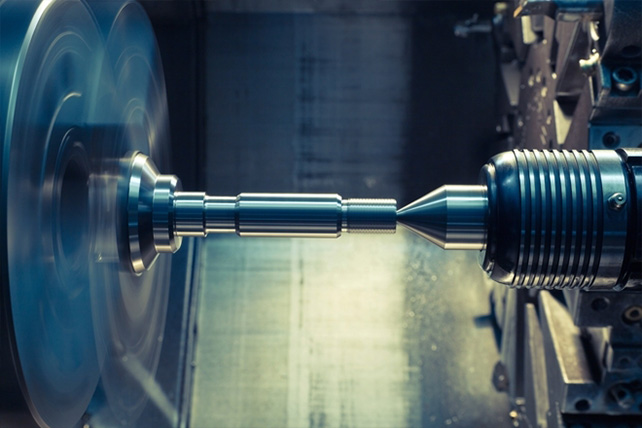

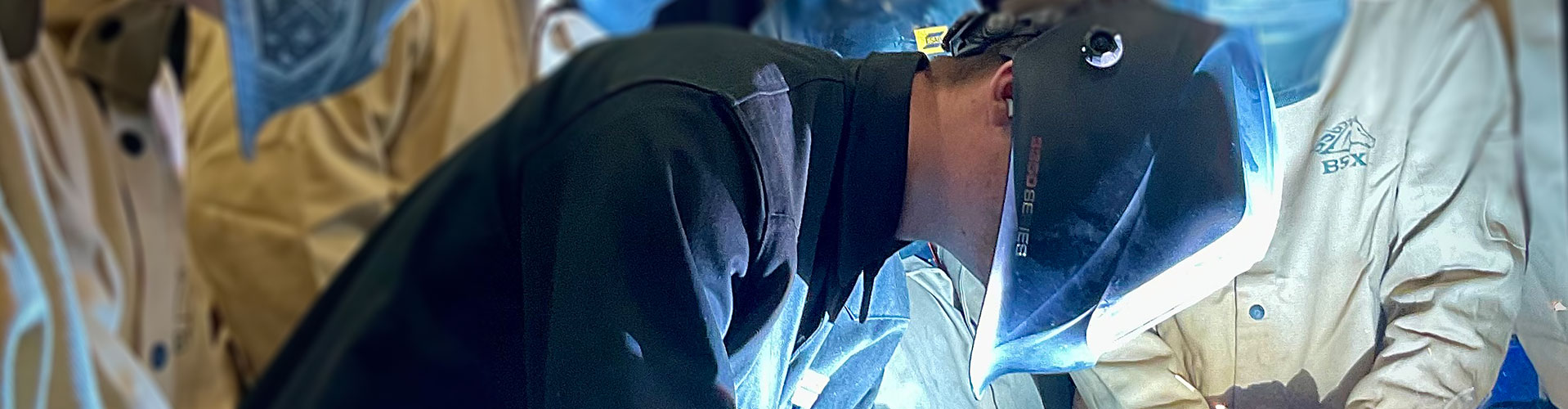

MERRILL makes anything possible. From concept to completion and beyond, our top-to-bottom capabilities mean that we can design, build, test and deliver nearly every operation imaginable.

Solutions

ANYTHING IS POSSIBLE

With the right people, the right values and the right technology, anything is possible. As a supplier to the aerospace, defense, energy, automation, transportation and heavy equipment markets for decades, MERRILL continues to prove that if you need it, MERRILL can make it. No matter what.

About

CONTACT MERRILL

To contact our Business Development Team, please fill out the form below.